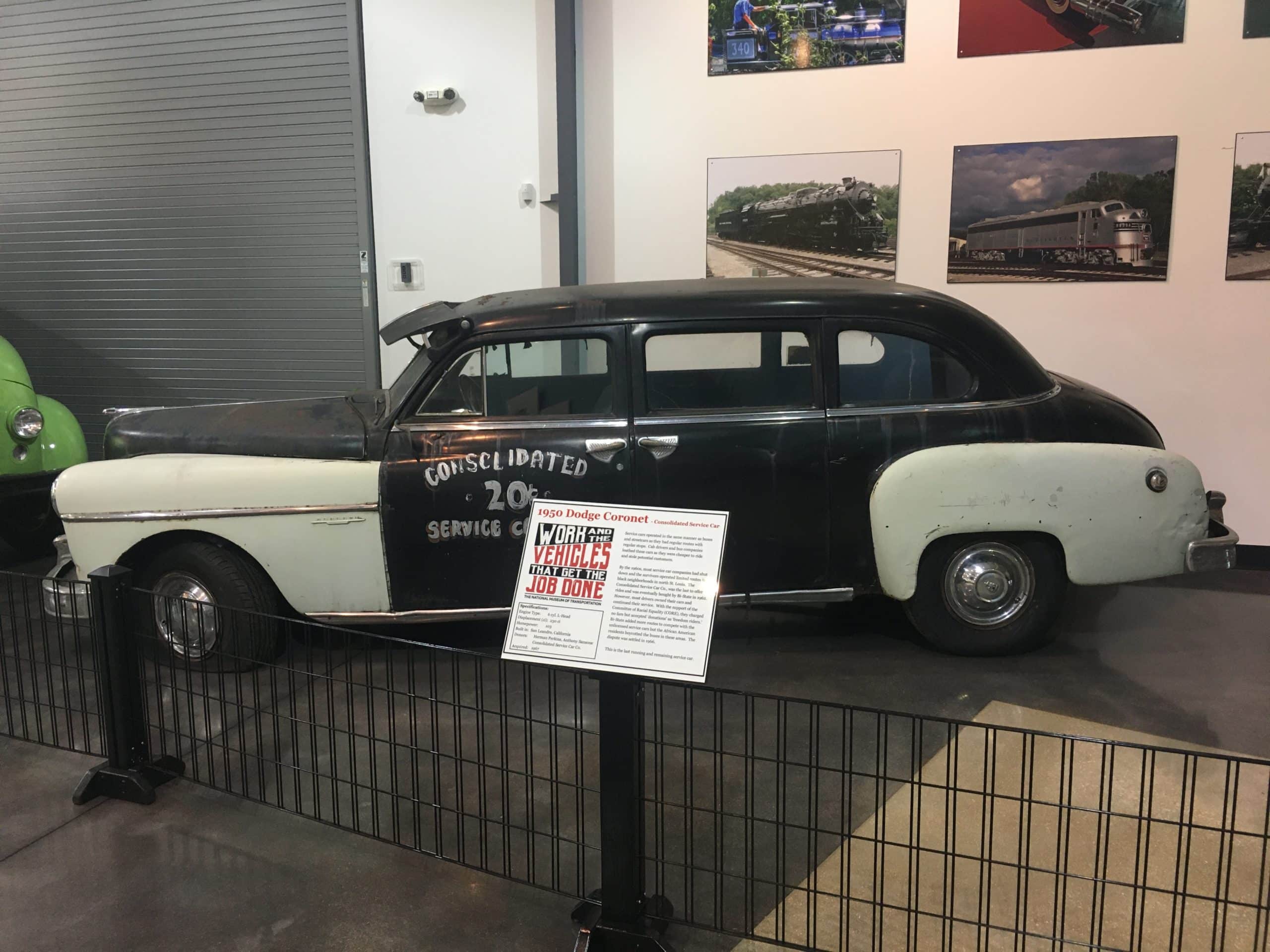

Constructing and maintaining the The National Museum of Transportation’s Demonstration Trolley Line and the trolleys/streetcars that ride thereon are no easy tasks. This work is on top of driving the trolley carrying customers who are greeted by our cheery volunteers dressed for the part.

The parts are not readily available for our trolley artifacts so some are cannibalized from surplus trolleys and streetcars or even fabricated. History may meet modern technology soon if a 3D printer needs to be employed to create a part that cannot otherwise be acquired. An intense amount of time and resources are spent planning and coordinating repair and restoration.

For instance when extending the trolley line at TNMOT, laying the track for the line extension was done by hand by the dedicated members of our track crew. This involved preparing the roadbed, laying gravel, ties, tie plates, rail, and spikes (which were driven in place using a pneumatic jackhammer), and finally, laying the ballast.

All that is left to do now is to erect the poles, string the wire, tie it into the existing system, add the 600-volt power supply and test it, still work but less time-consuming than laying track. Then, of course there is the ongoing maintenance and upkeep. It takes a lot! You will find the dedicated volunteer trolley maintenance crews very busy at work on Thursday and Saturday mornings.

Trivia: Railroad ties are cut to the same size and evenly spaced center to center. According to the American Association of Railroads, it takes 3,200 ties to lay one mile of track!